shonn

Member

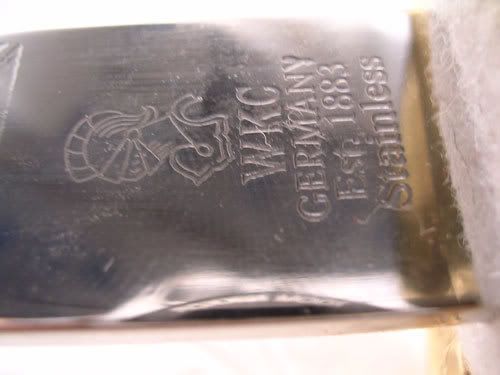

I have a fellow that would like his name and rank put on this sword..

Has anyone done this before?

I did not want to jump into something that may be too hard of metal for my carbide bits to cut. If anyone has some experience in this area please give me some advice.

Or if it is soft enough let me know.

Thank you for your time.

is there a special font that is normaly used for this kind of sword?

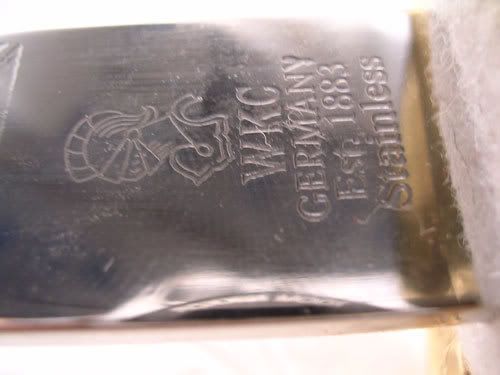

Has anyone done this before?

I did not want to jump into something that may be too hard of metal for my carbide bits to cut. If anyone has some experience in this area please give me some advice.

Or if it is soft enough let me know.

Thank you for your time.

is there a special font that is normaly used for this kind of sword?