You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

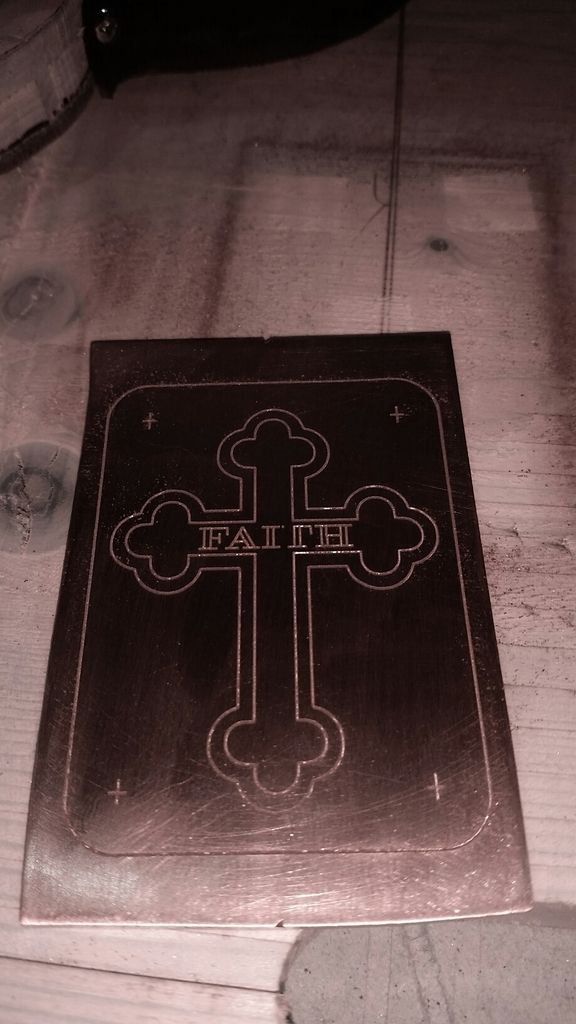

Need help please touching up a CNC engraved piece...

- Thread starter fretman_2

- Start date

atexascowboy2011

Elite Cafe Member

- Joined

- Feb 13, 2012

- Messages

- 997

Sam Alfano is close to you, Covington,La., and is a master engraver. Click on his name to contact.

Ron Spokovich

Elite Cafe Member

- Joined

- Dec 27, 2012

- Messages

- 436

If sufficient spacing exists, you can fix it. However, as this was apparently done with a rotary cutter under high speed, by the appearance of various radii throughout the cuts, you wouldn't be able to match up the cut's finish with a graver. The best deal may be to find a shop where someone skilled enough, with high speed spindle, could 'pick up' the cut and blend in perfectly, or at least to the naked eye. It can be done, but you only get one shot at it.

Chujybear

~ Elite 1000 Member ~

Or recut the whole thing with a graver.

if i was to do this-- i would correct the "t" by hand. match as closely as possible. if a perfect (to the eye" match) just didn't work-- one could go over the entire batch of lettering to make the word more even in appearance. if the letters did not exactly match the cutting in the cross, i don't think that would be an issue. if anything, it would make an acceptable contrast to the cross.

rmgreen

Elite Cafe Member

Scrap it

Scrap it. Chalk it up to experience. From the view of the picture provide there in not enough room to repair in any form and make it look as if it was not a "fixed" job. If repaired this will be the first thing seen and noted on the head. Have a real engraver do you a proper job and then it will never look like a fixer-up job.

Scrap it. Chalk it up to experience. From the view of the picture provide there in not enough room to repair in any form and make it look as if it was not a "fixed" job. If repaired this will be the first thing seen and noted on the head. Have a real engraver do you a proper job and then it will never look like a fixer-up job.

If it is copper as it looks I would agree with Roger. Just make another. If expensive metal, flip it over and redo on the other side.

glstrcowboy

Elite Cafe Member

If it was a CNC job why can't you rezero it and run it again? If you used a standard tapered single point tool, you should be able to cheat down .005 in Z and recut the whole thing just fine.

GTJC460

~ Elite 1000 Member ~

If it was a CNC job why can't you rezero it and run it again? If you used a standard tapered single point tool, you should be able to cheat down .005 in Z and recut the whole thing just fine.

I'm guessing that since its been removed from the machine it'll be darn near impossible to get it lined up correctly again.

diandwill

Elite Cafe Member

If you did the CNC, just re-do it on the back side. If you had it done, they screwed it up. They should re-do it for free.

glstrcowboy

Elite Cafe Member

Darn near impossible?! What? Well, yeah, it depends. I write most of my "one off" programs with X and Y set on center. With prototype work, there is a pretty good chance it is going back in the machine.

GTJC460

~ Elite 1000 Member ~

Depending on how it was fixtured, yes it can be redone easily.

However, I've spent roughly the last 10 years or so running 4 cnc machines to mill wax prototypes. Plus a Cnc engraving machine and a 3d printer. Most of the parts once they're removed from the machine make it very difficult to put it back to "recut" something.

You can only eyeball dead center and the cutter so good. Those stepper and servo motors are far more accurate than anyone's eyeball method. On a fine line you're pretty much wasting time trying to reposition it accurately. You might get close, but I doubt dead nuts on it.

However, I've spent roughly the last 10 years or so running 4 cnc machines to mill wax prototypes. Plus a Cnc engraving machine and a 3d printer. Most of the parts once they're removed from the machine make it very difficult to put it back to "recut" something.

You can only eyeball dead center and the cutter so good. Those stepper and servo motors are far more accurate than anyone's eyeball method. On a fine line you're pretty much wasting time trying to reposition it accurately. You might get close, but I doubt dead nuts on it.

glstrcowboy

Elite Cafe Member

No sir, no eyeballs here.  We set zeros with a ruby tipped digital probe. It measures to 0.0001, but repeatability is about 0.0005, all other factors constant. That's why I suggested cheating down 0.005; that should be enough to compensate for any variance in the reclamping. Anyway, probably a moot point and a better thread for the machining forum.

We set zeros with a ruby tipped digital probe. It measures to 0.0001, but repeatability is about 0.0005, all other factors constant. That's why I suggested cheating down 0.005; that should be enough to compensate for any variance in the reclamping. Anyway, probably a moot point and a better thread for the machining forum.