purplepepper8

Member

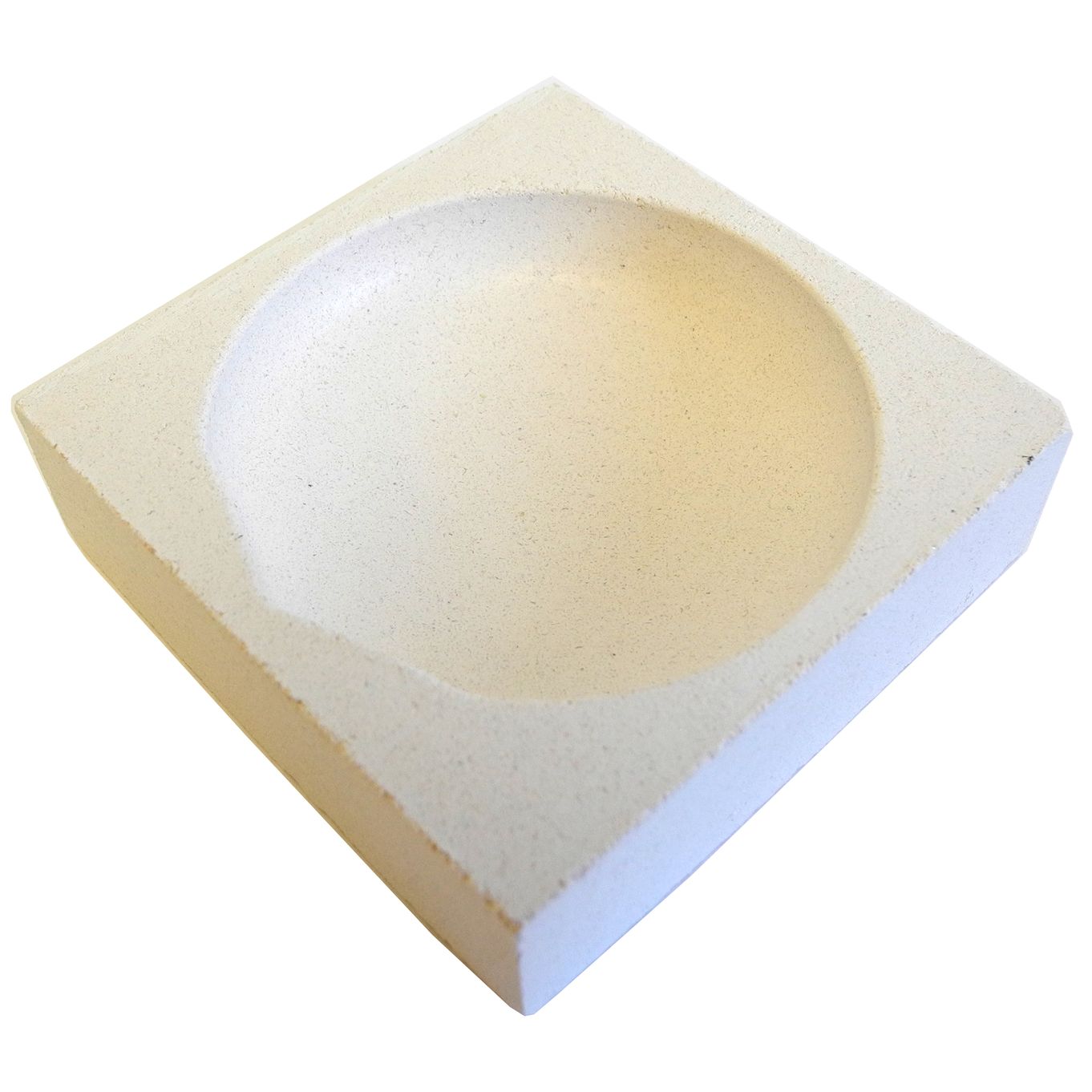

Hey, so far i have been getting alloyed gold sheets from another jeweller but figured now id start doing it myself. before trying with gold, i decided to practice with sterling silver (925 silver) since i haven’t done this before. each time i remelted the silver the weight would be around 2-3% less. i was wondering if this is normal? I found some tiny balls of silver stuck in the boric acid that coats the crucible (but the amount of that didn’t increase which each melt so the loss isn’t necessarily all getting stuck in the boric acid). Do some tiny bits fly out of the bowl with the force of the torch or get lost elsewhere? and wanted to ask if i should expect any loss with gold as well?

Lastly, how important is it to add boric acid powder while melting the metal?

FYI i am using the melting tip on the smith little torch and not a furnace.

Thanks

Lastly, how important is it to add boric acid powder while melting the metal?

FYI i am using the melting tip on the smith little torch and not a furnace.

Thanks

Last edited: