Barry Lee Hands

~ Elite 1000 Member ~

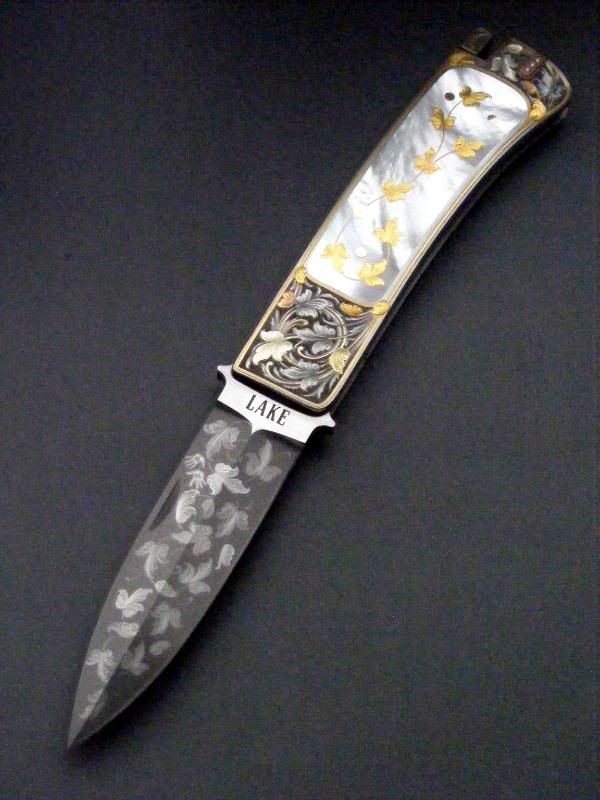

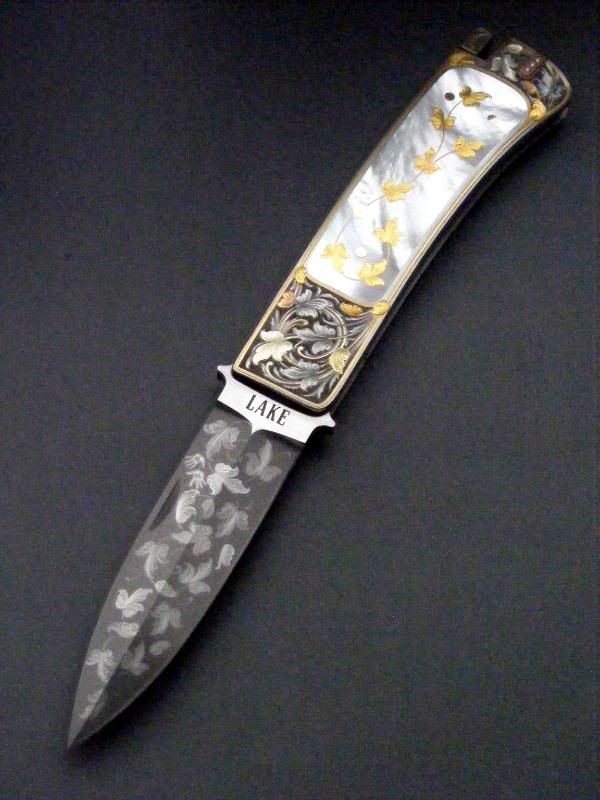

Ed has got a really great event coming up at which I will be debuting my latest work, a Ron Lake folding Dagger with Gilded pearl, and burnished blade technique, along with inductive layout designed Handstyle arabesque with five color virgin gold relieved inlay, and a diamond studded screwdriver(in case you need to repair your eyeglasses).

The 2010 Chicago Custom Knife Show will be held on Friday and Saturday, September 10-11, 2010, at the Holiday Inn Chicago Mart Plaza. Rooms are $149 per night.

Here is a link:

http://www.chicagocustomknifeshow.com/

Holiday Inn Chicago Mart Plaza

350 West Mart Center Drive

Chicago, Illinois 60654

(312)-836-5000

Reservations 800-315-2621

Show presenter

Ed Wormser

edw11@aol.com

Admission

$15 One day pass

$20 Two day pass

$30 VIP pass/Early admission

We look forward to your joining us!

Here is a peek at some of what I will be exhibiting:

The 2010 Chicago Custom Knife Show will be held on Friday and Saturday, September 10-11, 2010, at the Holiday Inn Chicago Mart Plaza. Rooms are $149 per night.

Here is a link:

http://www.chicagocustomknifeshow.com/

Holiday Inn Chicago Mart Plaza

350 West Mart Center Drive

Chicago, Illinois 60654

(312)-836-5000

Reservations 800-315-2621

Show presenter

Ed Wormser

edw11@aol.com

Admission

$15 One day pass

$20 Two day pass

$30 VIP pass/Early admission

We look forward to your joining us!

Here is a peek at some of what I will be exhibiting:

Last edited: