Jim Sackett

Elite Cafe Member

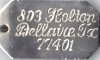

This is my 2nd try on this still not perfect but as good as I can do.

The sterling tag measures 13 x 8/16 the lower case letters are 1 1/2mm. This is the hardest engraving job I have ever done. The name on the other side will a little larger on two lines.

Any suggestions are welcome.

:beat up: Jim Sackett

The sterling tag measures 13 x 8/16 the lower case letters are 1 1/2mm. This is the hardest engraving job I have ever done. The name on the other side will a little larger on two lines.

Any suggestions are welcome.

:beat up: Jim Sackett