rweigel

Elite Cafe Member

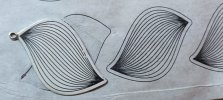

I’ve finally found a transfer method that works with my Brother laser printer. Brother’s laser toner is notorius for unreliable aceton or Dammar transfers. The advantages of my method are: no printer or toner modification, no expensive transfer paper or plastic sheet, no paper fibers left on the workpiece.

1. I print my design mirrored on A4 paper. I usually limit the design to A6 size.

2. I tape a piece of sandwich paper over the print (in German “Butterbrotpapier”, a paper to wrap sandwiches, very cheap, smooth, grease-tight, NO silicon involved). The sandwich paper shrinks slightly when it passes trough the fixing unit, therefore I use a piece not much bigger than the design to minimize warping. I use painters masking tape (paper backing, no plastic) to hold the sandwich paper in place. It was lying on my desk, it worked, no further reason for selecting it. Plastic backed tapes sometimes melt in the fixing unit.

3. I print the design again on the same sheet in the same direction.

4. I carefully remove the masking tape.

5. I paint the workpiece with Dammar solution (with some white oil paint mixed in to enhance contrast an reduce glare)

6. Once the Dammar is dried (some minutes), I put the printout on the sandwich paper printed-side down on the workpice and rub the back of the paper with a piece of hard plastic. Old credit card works, I use plastic spoons from our local icecream shop.

7. While holding the rest of the paper down with my left hand, I lift one corner of the paper and have a look at the transfer. If it’s OK, I remove the paper. If some lines are not perfect, I put the paper back down and rub the lines in question again with the plastic spoon. Then I remove the paper. The transfer is done.

Glue the piece to a wood block with hot melt anf a hot air gun, the heat involved fixes the Dammar with the laser toner at the same time.

Some of the Why’s:

The Sandwich paper is to flimsy and to slippery for the printers transport mechanism, it jams the printer. Hence the support with a 80g/m2 A4 sheet. The same measure was proposed for baking paper in other threads, it works well.

Why not using baking paper? Transfer was unreliable, it warps a lot in the fixing unit. I tried „better“ or „higher quality“ baking paper, presumably silicon coated. It did not take the toner at all, I had to remove the fixing unit and clean it.

Brother toner is wax and polypropylene based. I was attracted by the „grease tight“ quality of the sandwich paper, presuming that the laser toner would not penetrate it‘s surface. Seems I made a lucky guess…

Good luck repeating the procedure, cheers,

Ralf

1. I print my design mirrored on A4 paper. I usually limit the design to A6 size.

2. I tape a piece of sandwich paper over the print (in German “Butterbrotpapier”, a paper to wrap sandwiches, very cheap, smooth, grease-tight, NO silicon involved). The sandwich paper shrinks slightly when it passes trough the fixing unit, therefore I use a piece not much bigger than the design to minimize warping. I use painters masking tape (paper backing, no plastic) to hold the sandwich paper in place. It was lying on my desk, it worked, no further reason for selecting it. Plastic backed tapes sometimes melt in the fixing unit.

3. I print the design again on the same sheet in the same direction.

4. I carefully remove the masking tape.

5. I paint the workpiece with Dammar solution (with some white oil paint mixed in to enhance contrast an reduce glare)

6. Once the Dammar is dried (some minutes), I put the printout on the sandwich paper printed-side down on the workpice and rub the back of the paper with a piece of hard plastic. Old credit card works, I use plastic spoons from our local icecream shop.

7. While holding the rest of the paper down with my left hand, I lift one corner of the paper and have a look at the transfer. If it’s OK, I remove the paper. If some lines are not perfect, I put the paper back down and rub the lines in question again with the plastic spoon. Then I remove the paper. The transfer is done.

Glue the piece to a wood block with hot melt anf a hot air gun, the heat involved fixes the Dammar with the laser toner at the same time.

Some of the Why’s:

The Sandwich paper is to flimsy and to slippery for the printers transport mechanism, it jams the printer. Hence the support with a 80g/m2 A4 sheet. The same measure was proposed for baking paper in other threads, it works well.

Why not using baking paper? Transfer was unreliable, it warps a lot in the fixing unit. I tried „better“ or „higher quality“ baking paper, presumably silicon coated. It did not take the toner at all, I had to remove the fixing unit and clean it.

Brother toner is wax and polypropylene based. I was attracted by the „grease tight“ quality of the sandwich paper, presuming that the laser toner would not penetrate it‘s surface. Seems I made a lucky guess…

Good luck repeating the procedure, cheers,

Ralf