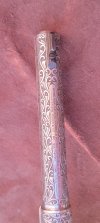

This is my second complete firearm engraving project, I started early in 2023 I worked on and off on it over about a years time before finishing it this spring, on this project I was trying to be a little more congruent in the pattern than with my first.

the grips were made from a piece of damascus steel and finished with nitrite bluing to achieve the straw brown color.

the grips were made from a piece of damascus steel and finished with nitrite bluing to achieve the straw brown color.

Attachments

-

20240801_202754.jpg138.7 KB · Views: 101

20240801_202754.jpg138.7 KB · Views: 101 -

20240801_202846.jpg141.6 KB · Views: 103

20240801_202846.jpg141.6 KB · Views: 103 -

20240801_202859.jpg138.5 KB · Views: 93

20240801_202859.jpg138.5 KB · Views: 93 -

20240801_202917.jpg124.5 KB · Views: 86

20240801_202917.jpg124.5 KB · Views: 86 -

20240801_202934.jpg116.4 KB · Views: 82

20240801_202934.jpg116.4 KB · Views: 82 -

20240801_203028.jpg100 KB · Views: 78

20240801_203028.jpg100 KB · Views: 78 -

20240801_203056.jpg104.6 KB · Views: 79

20240801_203056.jpg104.6 KB · Views: 79 -

20240801_203122.jpg62.6 KB · Views: 75

20240801_203122.jpg62.6 KB · Views: 75 -

20240801_203136.jpg64.6 KB · Views: 71

20240801_203136.jpg64.6 KB · Views: 71 -

20240801_203147.jpg60.7 KB · Views: 93

20240801_203147.jpg60.7 KB · Views: 93