Frank P

Elite Cafe Member

hello out there

here s a tip that works out very fine to me, only I regret i never came sooner to the idea

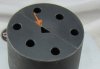

the GRS ball vise comes standard with a vertical groove in the middle of one jaw...

I made a horizontal one on the other... and it makes life much easier to hold odd shapes and tilted things..

hope it helps someone like it helped me...

have a nice Weekend

Frank

here s a tip that works out very fine to me, only I regret i never came sooner to the idea

the GRS ball vise comes standard with a vertical groove in the middle of one jaw...

I made a horizontal one on the other... and it makes life much easier to hold odd shapes and tilted things..

hope it helps someone like it helped me...

have a nice Weekend

Frank

Attachments

Last edited: