Jenny2

Member

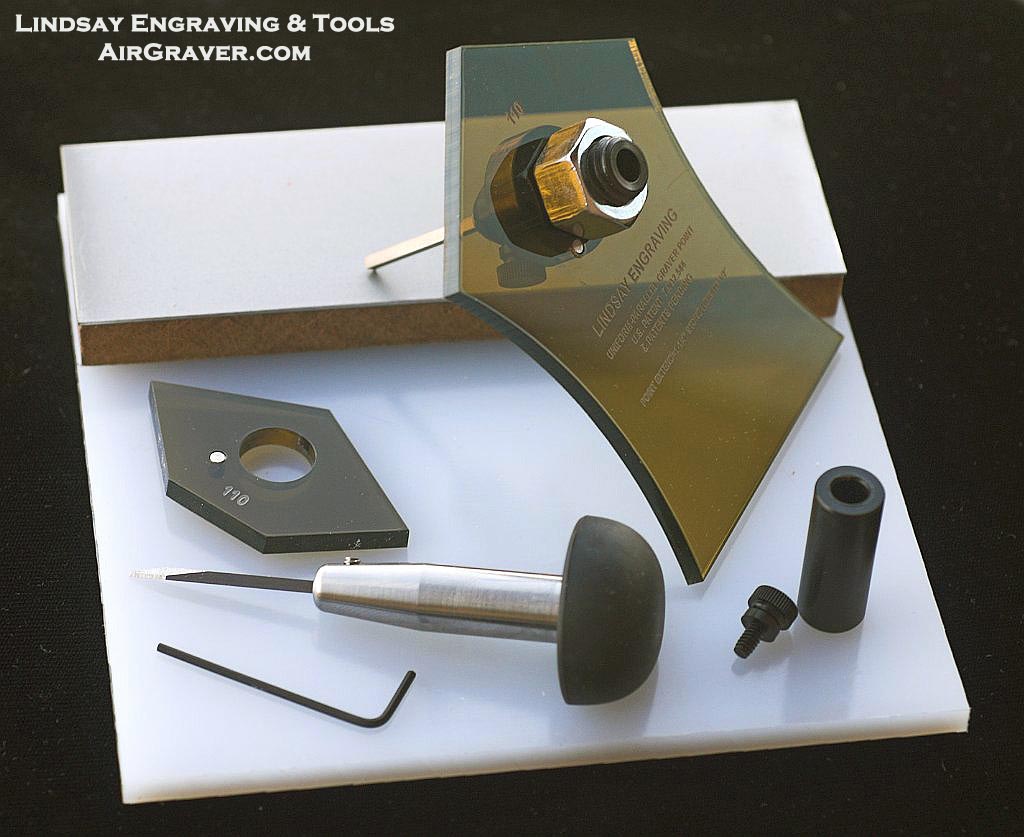

It looks like the manufacturer makes another diamond pad that might work. I'll give it a try. It isn't as wide as the new one, but that may benefit me due to space on the grinder as i need room for the templates. These diamond pads are very useful in my glass work if they don't work for metal sharpening, so nothing is going to waste. It would just be great to have one piece of equipment function for more than one type of work. I'll mainly use the hand pads, but again it would be nice to have an option at least for the first rough pass of the graver. Thanks for your comments.First you need to make a precise measurements. Up to 0.1mm. Knowing diameters of the central rod, bottom mandrel and a small hole in the diamond disk will help you choose the right mandrel adapter. You can buy such adapter or someone with a lathe can do it for you. Drill press is not precise for such a work.

Last edited: