Joe Mason

Elite Cafe Member

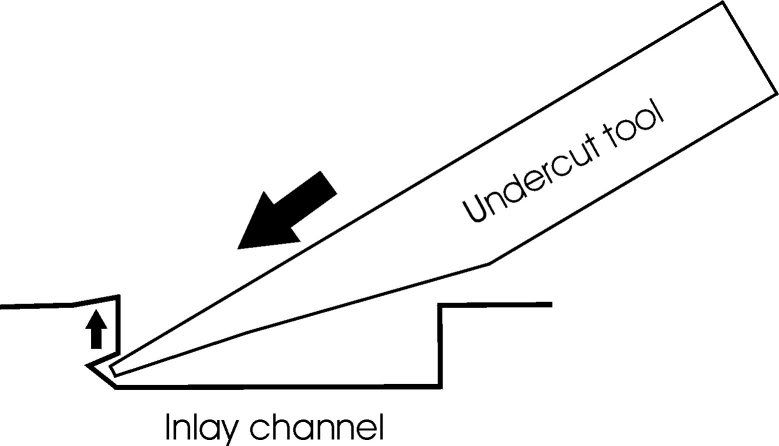

Here is a drawing I did of my inlay tool.

Joe

Joe

Sam- i'm surprised to learn you don't do it like Lynton. he showed me about 25 yrs ago and it literally changed my life, at least in a gold-inlaying sense...