Jeremy.thejeweler

Member

- Joined

- Apr 9, 2021

- Messages

- 13

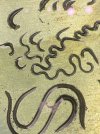

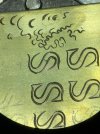

Please please please help.

I’m a bench jeweler and I’ve been learning engraving for a few months now, but not very consistently because of my full regular workload. I still try to put in at least ten to fifteen hours a week though. I can not stop this heel drag with tight corners, and even not so tight corners.

It happens when I try to bright cut letters with flats, with my 120, 105, and 90. Every graver and every geometry is giving me this problem. Even my Lindsay’s.

I have an apex sharpening system and all of Sam’s DVDs. I make the heels EXACTLY as he says, the exact width of a mark on a ruler. It doesn’t matter if I engrave deep or if I’m engraving incredibly shallow, there is always some sort of heel drag on curves.

I’ve tried every heel angle from 10 to 40. I feel like I’ve tried absolutely everything.

I’ve tried holding the graver at damn near every angle except 90 degrees straight down to the work and it’s on almost every curve almost every time. I keep my hand completely still and only turn the vise. I don’t move the graver into the turns it’s completely still. I have even tried rolling the graver to the inside or outside of the curve. I’ve tried everything. Absolutely everything. It’s driving me absolutely insaneeeeeee.

Also, I’m using a pulsegraver if that means anything.

Please. Please. Please help. I’m going crazy over here.

I’m a bench jeweler and I’ve been learning engraving for a few months now, but not very consistently because of my full regular workload. I still try to put in at least ten to fifteen hours a week though. I can not stop this heel drag with tight corners, and even not so tight corners.

It happens when I try to bright cut letters with flats, with my 120, 105, and 90. Every graver and every geometry is giving me this problem. Even my Lindsay’s.

I have an apex sharpening system and all of Sam’s DVDs. I make the heels EXACTLY as he says, the exact width of a mark on a ruler. It doesn’t matter if I engrave deep or if I’m engraving incredibly shallow, there is always some sort of heel drag on curves.

I’ve tried every heel angle from 10 to 40. I feel like I’ve tried absolutely everything.

I’ve tried holding the graver at damn near every angle except 90 degrees straight down to the work and it’s on almost every curve almost every time. I keep my hand completely still and only turn the vise. I don’t move the graver into the turns it’s completely still. I have even tried rolling the graver to the inside or outside of the curve. I’ve tried everything. Absolutely everything. It’s driving me absolutely insaneeeeeee.

Also, I’m using a pulsegraver if that means anything.

Please. Please. Please help. I’m going crazy over here.

Attachments

-

F80551CC-8F22-493F-8F04-C102190C9947.jpeg223 KB · Views: 147

F80551CC-8F22-493F-8F04-C102190C9947.jpeg223 KB · Views: 147 -

3F8664F5-C46D-4806-90CE-8704AB95B3B8.jpeg222.3 KB · Views: 132

3F8664F5-C46D-4806-90CE-8704AB95B3B8.jpeg222.3 KB · Views: 132 -

E7F7A918-FF82-4A57-A556-B540673AB3FC.jpeg188.1 KB · Views: 119

E7F7A918-FF82-4A57-A556-B540673AB3FC.jpeg188.1 KB · Views: 119 -

E9EDAE8D-4C69-42A7-BAD2-883DCE4D8BD7.jpeg186.8 KB · Views: 128

E9EDAE8D-4C69-42A7-BAD2-883DCE4D8BD7.jpeg186.8 KB · Views: 128 -

1CEFA5DF-851B-45B5-86F8-AE9846123DF3.jpeg204.4 KB · Views: 137

1CEFA5DF-851B-45B5-86F8-AE9846123DF3.jpeg204.4 KB · Views: 137