Tira

~ Elite 1000 Member ~

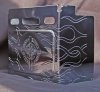

Here are the latest parts I did for a client. They include the battery case and top for the right side of the bike and two electrical case covers that bolt together on the left side. The eagle/cross design is special to the client - it is a roadside sign in Europe at his favorite place in the mountains. The flames trail towards the back of the bike on each side. All the parts were steel and were chromed after the engraving.