I think I'll try the foredom 1040 and post a video of how it goes. I'll keep working on my grip too. I tried again the other night and simply can't get a ball bur into soft metal more than 1/3 of the way without it chattering. I hope this helps.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

still kicking

- Thread starter Dani Girl

- Start date

who makes the best burs for setting? especially pave. I should order a few top notch burs to use with the tool when it arrives in a month or two depending on customs delays. lots of time for watching videos til then.

farmer57

Member

You will probably get many opinions here. I've used Busch brand carbide burs the most, they work very well. Also have used Lynx brand and those are OK but not for everything. Technique has a line of burs that is on cheaper side, I've only used their saw burs (not carbide) and so far these hold up well for silver and gold and copper.

Whatever you use, carbide will last the longest - as long as you lube burs often and don't 'force' the cutting.

Whatever you use, carbide will last the longest - as long as you lube burs often and don't 'force' the cutting.

thanks farmer. I've ordered a couple of busch carbide. I do love carbide. I did have a close look at the teeth on some of my setting burs and while they're all still there I was unimpressed with the evenness... one tooth wasn't shaped quite right on one bur. I'll do a good test video of both machines using all the different kind of burs and share it for folks benefit. I can't say how much I appreciate the advise and experience everyone's shared.

this is a link to a tri microscope. does anyone know if it would be any good for engraving and showing what you're doing or if there is a half decent budget model anyone would recommend?

Here's one of the promised videos... this one just shows how quiet the Foredom 1040 is compared to the previous tool that lacked a gradual speed foot pedal. I've set one stone with it so far, one can still do it wrong and get chatter but when you slow it right down and do it right it's possible. The busch pave setting burs with the drill tip and round bur in one are SO sooooooo nice.

this link might work better

I've laid out the project for the day. This can be a quick design transfer method. Easy to peel off and rinse away paper glue. bees wax wiped over the metal and stones placed upside down. I think I'll use my scrim scribe to put lots of dots around each so I know where they'll all go. 2mm, 1.5mm, 1mm. cz and bronze. anyone see any issues with the stone layout. metal should be just thick enough

tonight's effort. one broken stainless drill. one broken busch carbide drill, which before I got to it was an absolutely gorgeous creation, got to get some more of them and not break them. I managed to make dents accross the rest with the busch pave bur/drill. I scribed and made little dents with a ball bur before starting to discourage drill wandering.

I'm really fighting burring the holes out with the set of setting burs I bought in a wooden box. maybe tomorrow I'll try some different burs. I'm trying to go super slow, 500rpm-1,000rpm and that's reducing the chatter mostly.

I'm really fighting burring the holes out with the set of setting burs I bought in a wooden box. maybe tomorrow I'll try some different burs. I'm trying to go super slow, 500rpm-1,000rpm and that's reducing the chatter mostly.

regarding afore mentioned broken drills, I punched them out with a broken bur I'd saved after burring out the back of the metal til I got to the drill with relative ease, got my punch stuck and broke it too but seeing it was tapered I turned it over and punched it out from the other side. I got through 20 odd holes with this one before I wobbled and snapped it.

admittedly I didn't try every bur in each box but what I did note is that of these 3 sets I bought off of Rio grande years back. the Swiss burs chattered like mad. the maliffer carbide burs cut this fascinating ?7 sided roundish facet as they kind of bounce around in the holes and the best seem to be the wooden box of no name setting burs. conclusion = there are round burs and there are setting burs.

ok so matching drill size to bur size you're going to finish at is more important than I'd thought. too big and it's really easy to slip clean out the other side. too small and the round but doesn't want to go through. round burs don't really cut on the top. busch pave burs do away with all that with drill/bur in one. pricey to set up with bur they're so nice and easy to use. $37aud via Australian jewellers supplies per bur. I found some fox carbide burs on ebay but I'm too worried I'll get the same results off my standard round burs so I think I'll have to go busch. any suggestions of other brands and where to purchase?

I've yet to use aliexpress

rweigel

Elite Cafe Member

I would not dare to use machine drills made from carbide (the one with the red marker ring) in a handpiece, as they break like glass. I use tool steel drills 0.5 or 0.6 mm for the pilot hole, and often have to correct their grind after inspecting them under the microscope.

The enlarged photo of the hole shows chatter. If the handpiece controller permits reverse rotation, try this. It drills slower but without chatter.

Cheers

Ralf

The enlarged photo of the hole shows chatter. If the handpiece controller permits reverse rotation, try this. It drills slower but without chatter.

Cheers

Ralf

i see Alexander likes busch.

www.instagram.com

www.instagram.com

I do enjoy watching him work... especially on the box with the textured inlay and quatrafoil. .

this is a good little snippet on sharpening tips for protractors

www.instagram.com

www.instagram.com

Alexandre Setting School on Instagram: "Yes ✅ We’re Open - Belgium - official & dealer @buschjewellery located in Antwerp, Belgium We help our locals to choose the right tools for the job and provide long term support! Come visit us at: . . Ap

402 likes, 11 comments - alexandreschool on September 2, 2024: "Yes ✅ We’re Open - Belgium - official & dealer @buschjewellery located in Antwerp, Belgium We help our locals to choose the right tools for the job and provide long term support! Come visit us at: . . Appelmansstraat 25, Shop...

www.instagram.com

www.instagram.com

I do enjoy watching him work... especially on the box with the textured inlay and quatrafoil. .

this is a good little snippet on sharpening tips for protractors

Alexandre Setting School on Instagram: "Here's a mini-tutorial on how to sharpen and polish a pair of replaceable carbide tips on your AlexTools divider. #alextools #alexandreschool #tutorial #divider #diamondsetting #engraving"

580 likes, 15 comments - alexandreschool on June 5, 2017: "Here's a mini-tutorial on how to sharpen and polish a pair of replaceable carbide tips on your AlexTools divider. #alextools #alexandreschool #tutorial #divider #diamondsetting #engraving".

www.instagram.com

www.instagram.com

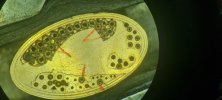

any advice for a stone setting newbie who's only watched YouTube videos. I think I've stuck like 8 stones into metal to date. I'm fascinated by what the bottom of the drill holes look like, I guess I didn't drill large enough?

Busch burs make so much difference. The carbide ones will last longer, enable cutting harder materials and even cut nicer in this bronze... they cost a bit more but i really love my carbide. I can't say how nice the pave ones that drill and bur at the same time are to use. I would recommend the purchase of one of those and some czs of the same size if one wanted to try. koodak jewellers supplies in Australia are doing a special on busch at the moment.