I made a previous post but perhaps this will clarify my issue more. I was unable to make a parallel heel with my dual angle fixture correctly. I watched Tira's video on sharpening along with Sam's. Sam instructed to use a ceramic lap to make a .25mm heel. Tira used what looked like a much larger traditional heel and a diamond wheel then polished it. I tried with a 1200 grit wheel and got a traditional heel that is a hair larger than .25mm but it is easier to make very tight curves without any heel drag. The cut does not look great because I'm assuming its not polished. Does the ceramic lap actually take any material off of the graver to achieve the angled heel? I don't have much experience in this and imp trying to find a method that works and that i can repeat time and time again. I understand that what may work for one person does not work for another. I feel like I am missing something in the process of making these gravers. If I can get it to work with a traditional heal that would be great given my sharpening system I have. Thank you for any help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Updated heel questions

- Thread starter jkaragias

- Start date

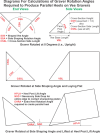

A parallel heel is made with a slightly higher angle than the side angles you’re cutting into the graver; if you’re making a 90° square graver, each side is cut at a 45° From vertical and the heel would be cut at a 55°-ish (this is the angle that different people do differently) angle to make a facet along the whole length of the side instead of a small triangle at the tip. The diamond powder on the ceramic lap or diamond wheel does remove material from the graver to form the heel. It’s not like polishing with rouge, it’s still an abrasive process that removes a small amount of material, which is what you need to form the heel.

AllenClapp

Elite Cafe Member

You can make parallel heels with the dual angle fixture. Here is page 1 of the results for common graver angles. To get a parallel heel, you must rotate the graver over more than the shape angle to get the whole side down on the graver. This is a function of the face angle, the shape angle, and the heel angle. I will post the other sheet separately.